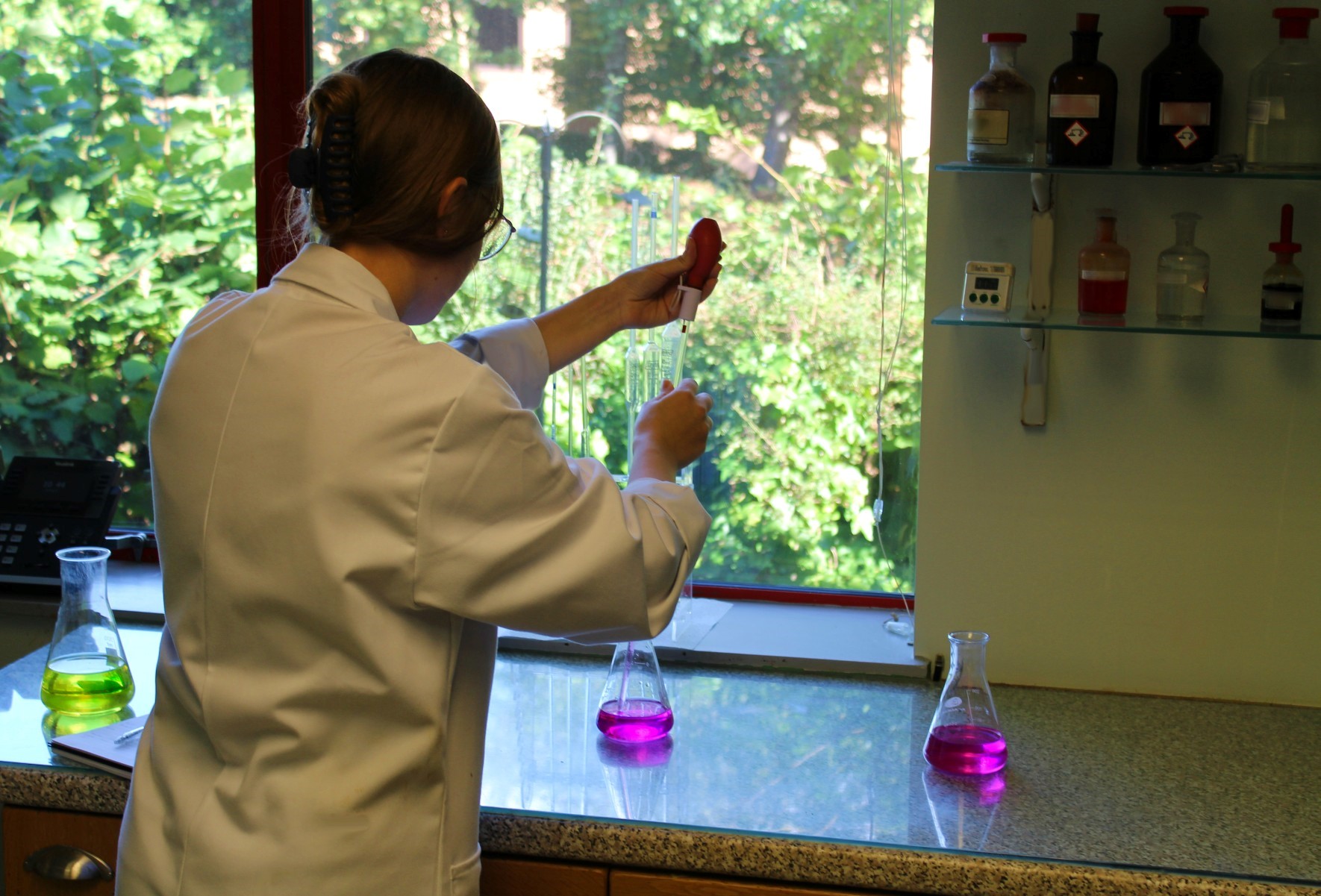

Chemical Analysis

for Process Solution Control

Chemical analysis is a core function of Aerotech Laboratories Ltd and we are UKAS accredited to ISO/IEC 17025 for a large range of services we offer in this respect.

The accurate control of process solutions used to treat metal surfaces is one key imperative of any robust quality system and many specifications demand this level of control.

Furthermore, due to our independence we always provide an impartial and balanced response to any analytical requirement.

As with our other services we predominately support the aerospace, automotive and defence sectors along with the wider metal finishing industry and the types of solutions that we can analyse include:-

| Electro-plating | hard chrome, cadmium, nickel, copper, bronze, zinc, silver, tin | |

| Anodising & Conversion Coatings | chromic acid, sulphuric acid, titanium anodise, phosphate, chromate, Alocrom, Alodine | |

| Electrochemical & Chemical Machining | STEM drill, capillary drill, dielectric fluids, chemical machining | |

| Etching & Pre-Treatments | inspection etch, de-smut | |

| Surface Conditioning & Cleaning | dichromate seal, descalers, vapour degreasers, de-rusting, De-Oxidiser 7-17, proprietary aqueous cleaners – M-Aero, Oakite, Ardrox, Orthosil, Aloclene, Turco, Metsoak, Bluegold, Surfos C152, Solvex ICD173, Trimite | |

| Oils & Solvents | paraffin, white spirit, Lanolin, quench oil |

We can also design a programme of testing that serves the needs of your organisation whereby we can be seen as your own in-house laboratory.

This includes flexibility for each aspect of the our service portfolio :-

- to provide results at timescales defined by the customer, e.g. next day reporting

- to supply results using any combination of media, e.g. phone, email, hard copy

- to design and agree a testing regime to satisfy control specifications as required

- to negotiate a pricing structure that meets a budgetary need

- to agree a payment schedule to align with financial accounting processes

- to offer a range of service levels; from ad-hoc testing to total laboratory support

Additional Analysis

In addition to the analysis of chemical process solutions there are number of peripheral functions that are integral to the successful end to end operation of any facility. We offer various products and analytical services to support our customer’s production systems.

Monitor

Metal finishing facilities are required to monitor and control wastewater / effluent discharge under the regulations of statutory authorities, e.g. regional water companies and the Environment Agency. Aerotech Laboratories Ltd offer a variety of analysis services in order to minimise the risk of infringing discharge consents covering; Chemical Oxygen Demand (COD), suspended solids, acidity/alkalinity and various dissolved toxic metals.

Measure – Health and Safety Executive

& COSHH Regulations

The measurement of airborne pollutants from industrial processes e.g. dust, fumes and vapours, is a significant requirement in order to comply with the COSHH regulations prescribed by the Health and Safety Executive (HSE).

In particular we have a variety of products and services for the measurement and control of Chromic Acid Mist (CAM) as detailed in the HSE specification MDHS 52/4.

This includes the manufacture of Alkali Treated Filter Membranes, reagents and chemical kits along with a rental option for an aspirator.

Nadcap – Aerospace Quality Systems

The Performance Review Institute (PRI) administer and manage key programmes to “improve manufacturing process and product quality by adding value, reducing total cost and promoting teaming between global stakeholders in the mobility and other interested industries.”

One such key programme is Nadcap, which is “an industry-managed, consensus approach to OEM oversight of special process and product suppliers. Nadcap is an integral part of the supplier management system of most of the world’s aerospace manufacturers.”

Furthermore, Nadcap recognizes ISO 17025 for testing laboratories, including non-destructive testing laboratories. The ISO 17025 scope of accreditation must cover the Nadcap scope of accreditation and be from an approved NACLA / ILAC accreditation body.

Suppliers who have an ISO 17025 accreditation approved by NACLA / ILAC do not require an additional quality systems audit through Nadcap.

For more information visit the Nadcap Aerospace Quality Systems website

Flexible and Cost effective

Our standard pricing principle is based on a “per sample” cost, irrespective of the number of determinations carried out on that sample. To make the whole process simple we will provide labelled sample bottles and reports are issued via email using PDF attachments showing the relevant accreditation and an authorised signature.

Discounts are offered for increased quantities and frequencies; please contact us to discuss your requirements.

Corporate Approvals

In addition to our UKAS and Nadcap Accreditations we hold many corporate approvals including :-