Salt Spray

Aerotech Laboratories Ltd are UKAS Accredited for performance testing of coating and engineering surface finishes using salt spray accelerated corrosion testing to American, European and British specifications.

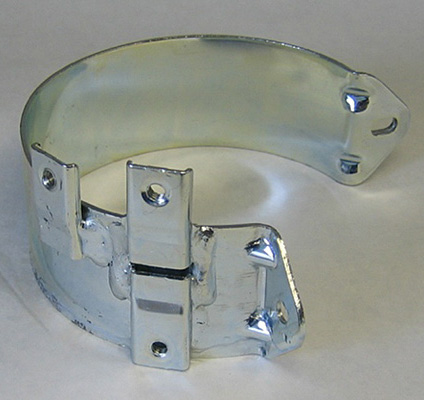

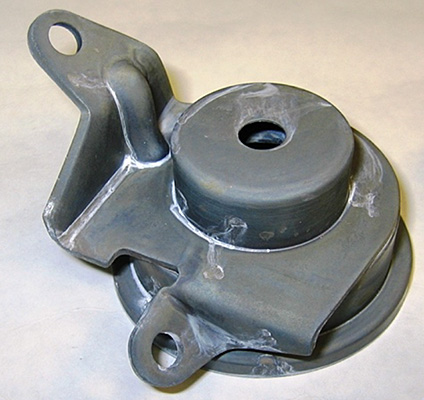

Salt spray accelerated corrosion testing is used extensively across the metal finishing industry as a Quality Control procedure to monitor the performance of chemical processing and to facilitate continuous improvement programmes. It is also an effective test method for Process Validation used during the design and implementation phases to confirm the suitability of various surface finishing techniques.

We operate 3 test cabinets with a total cubic capacity of 1,500 litres, the largest of which has internal dimensions of length 1465mm, width 1040mm and height 720mm (rising to 1065mm at the lid apex). They run 24 hours a day, 7 days a week and for 365 days of the year.

These test cabinets deliver the precise test conditions required with reliability, ease of operation and a robust construction. The accelerated corrosion testing service is used in all major manufacturing sectors including aerospace, automotive, defence and building and construction, for all types of coatings and finishes.

The test cabinets conform to all leading corporate, national and international standards including:-

ISO 7253, BS 3900 F12, ASTM B117, DIN 50.021, Toyota TSH 1555G, Ford EU B 153-2, VDA 624-415, VW-1210-C, Renault, JIS-K 5622-7, SWAAT+Mastmaasis, Honda 5100Z, GM 954 P, Nissan M0007, Unichem 692 & 741.

Anyone who carries out salt spray corrosion testing and uses the common American specification ASTM B117 for controlling exposure conditions should know of important changes in the type of salt allowed. These changes were introduced in 2003 and are contained in the latest issue of ASTM B117, as follows:-

- the salt cannot have any anti-caking agent added, sometimes listed by their technical names potassium (or sodium) ferrocyanide, potassium hexacyanoferrate II, or the chemical formula K4Fe(CN)6

- the amount of copper must not exceed 0.3 parts per million by weight – that’s a maximum of 0.3 mg of copper per kilogram of salt or 0.00003%

- total fluoride, iodide and bromide must be no more than 0.1% by weight

Aerotech Laboratories Ltd only uses salt that conforms to these requirements.

Test specifications:-

ASTM B117

ISO 9227:2007 (E)

BS EN 1670:1998 (in conjunction with performance rating method BS EN 10289:2001)

BS EN 248:2002 (E)

MIL-STD-810F Method 509.4

Our standard pricing principle is based on a “per sample” cost, irrespective of duration of exposure required and physical dimensions of the sample (as long as it fits in the cabinet).

Discounts are offered for increased quantities and increased frequencies so please contact us to discuss your requirements in detail.

We are able to provide digital photos of test specimens at interim stages during the exposure period or after the tests are complete.